Installation and Direction

1. For best results, use carbide tipped blades and router bits.

PERTH Tip: Blades with fewer teeth (18-24 for 45cm circular saw blade) work best.

2. PERTH® WPC lumber’s workability is outstanding. Unlike wood, with PERTH® WPC lumber you won’t need to be concerned about grain direction or knots.

3. When drilling large or deep holes, periodically lift the drill out of the hole to draw the shavings out.

1. PERTH® WPC lumber weighs more than wood and it’s more flexible. Special care should be taken when handling.

2. When storing PERTH® WPC lumber at the job site, be sure to place on a flat surface.

3. When stacking units, supports should start at each end and be spaced 60cm on center. Supports should line up vertically .

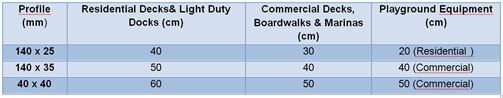

In most installations, a span of 60cm on center using a minimum of 3 joists will provide excellent results. Please refer to Table 1 of PERTH® Decking Span Chart (1)’ and Table 2 of PERTH® Decking Span Chart (2)’ .

1. S tainless steel or nickel-plated nails or screws are highly recommended to take full advantage of the durability of PERTH® WPC lumber.

2. More force is required to drive a nail into PERTH® WPC lumber than regular wood. Hold nail while hammering until it is driven 1.5cm to 2cm . Hitting a nail with full force when it is not driven in may cause it to fly out. Nail guns work very well with PERTH® WPC lumber.

3. For cold weather installations or when using wood screws or lag bolts, pre-drilling may be necessary. Do not drill holes any larger than 3/4 of the screw/bolt diameter.

4. Most screws will cause PERTH® WPC lumber to “mushroom” up over the screw head. Simply tap down with a hammer to hide the fastener or pre-drill to reduce the “mushroom” effect.

5. To the kind of PERTH® WPC whose width is more than 10cm , two nails or screws should be used at the same position.

Notes:

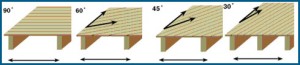

1)When the angle of decking board to joints is just like Sig.1, see Table 2 of ‘ PERTH® Decking Span Chart (2)’ .

2)Special applications or unusual loading conditions-such as hot tub installations-may require shorter spans. In these cases, obtain an engineering analysis before installation.

Gapping is necessary to allow for drainage and cleaning and also to allow for the slight thermal expansion and contraction of PERTH® decking.

Width-to-Width: For width-to-width gap required is 6mm . For cold weather installations, 10mm is recommended.

End-to-End:

PERTH® decking must also be gapped end-to-end, based upon the length of the board, the temperature at installation, the highest temperature expected during the year and the Coefficient of Thermal Expansion/Contraction( -4 )

Counting the gapping of END-to-END:

for L long PERTH® decking, the highest temperature expected during the year is Tmax £¬ the temperature at installation is T, then the gapping of END-to-END is .

EXAMPLE:

A PERTH® decking’ long is 2 meters, the temperature at installation is 10, the highest temperature expected during the year is 40, so the gapping of END-to-END is :

=2000 x (40-10) x 0.9 x 10-4

= 5.4mm

Notes : PERTH® decking must always be installed properly gapped and directly on joists. Do not attach PERTH® decking to any solid surface or water tight system such as sheathing, waterproof membranes, concrete, roof systems or patios.

Cleaning

1. For stains caused by mold, mildew, berries and leaves, conventional deck washes containing detergent and sodium hypochlorite work well.

2. For rust stains, ground-in dirt and grime, use cleaners containing phosphoric acid which are commonly available in home centers and hardware stores.

3. For tougher stains, such as oil or grease, scrub with a detergent containing a degreasing agent as soon as the stain occurs.

PERTH Tips: A light sanding with a medium grit sandpaper works well in removing grease stains that have been allowed to set. This area will weather again as it did after installation.

4. Periodically clean out expansion gaps between PERTH® boards with a flat tool to ensure proper drainage.